Plastic, a versatile and widely used material in various industries, has become an integral part of our daily lives. From packaging materials to automotive components, plastics offer numerous benefits due to their durability, flexibility, and cost-effectiveness. In this article, we will delve into the world of plastic raw materials, exploring their types, properties, and diverse applications.

Introduction

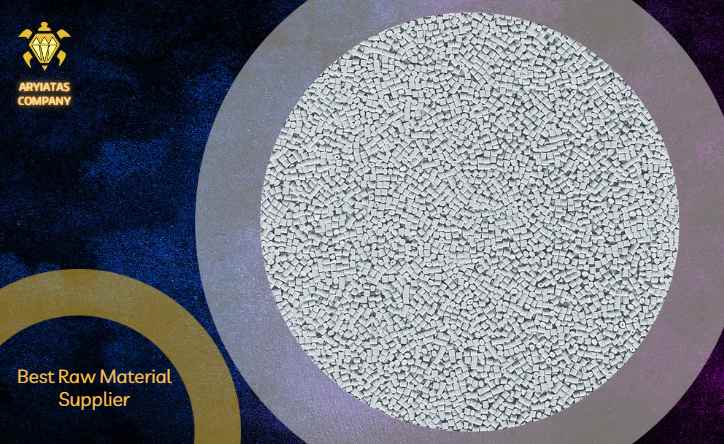

Plastic raw materials serve as the building blocks for manufacturing various plastic products. They are derived from petrochemical sources and undergo a complex process to form different types of plastics. Plastic raw materials offer a wide range of properties, enabling manufacturers to tailor them to specific applications. Understanding the different types and properties of plastic raw materials is crucial for utilizing them effectively in diverse industries.

What is Plastic Raw Material?

Plastic raw material refers to the base substance used in the production of plastic products. It acts as a precursor, undergoing various processing techniques to form different types of plastics with unique characteristics. They are typically derived from petroleum, natural gas, or renewable sources such as biomass.

Types of Plastic Raw Materials

Plastic raw materials can be classified into several types based on their chemical composition and properties. Some of the commonly used it includes:

Polyethylene (PE)

Polyethylene, a thermoplastic polymer, is the most widely used plastic raw material. It is known for its excellent toughness, chemical resistance, and electrical insulation properties. PE is commonly used in packaging films, containers, pipes, and toys.

Polypropylene (PP)

Polypropylene is a versatile plastic raw material known for its high strength, heat resistance, and low density. It finds applications in various industries, including automotive components, household goods, and medical devices.

Polyvinyl Chloride (PVC)

Polyvinyl Chloride, or PVC, is a widely used plastic raw material due to its excellent durability, flame resistance, and chemical stability. It is extensively utilized in construction materials, electrical cables, and vinyl records.

Polystyrene (PS)

Polystyrene is a lightweight plastic raw material with good insulation properties. It is commonly used in packaging materials, disposable cutlery, and insulation foams.

Polyethylene Terephthalate (PET)

Polyethylene Terephthalate, or PET, is a strong and transparent plastic raw material. It is widely used in the production of beverage bottles, food containers, and textile fibers.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a durable and impact-resistant plastic raw material. It finds applications in automotive parts, electronic housings, and consumer goods.

Polyurethane (PU)

Polyurethane is a versatile plastic raw material with excellent elasticity, durability, and chemical resistance. It is used in upholstery, insulation, adhesives, and coatings.

Others

There are numerous other types of plastic raw materials, including polycarbonate (PC), polyvinylidene fluoride (PVDF), nylon, and more. Each type possesses unique properties suitable for specific applications.

Properties of Plastic Raw Materials

Plastic raw materials exhibit a wide range of properties that make them suitable for various applications. These properties can be categorized into physical, chemical, and mechanical properties.

Physical Properties

Physical properties of plastic raw materials include density, melting point, transparency, color, and surface texture. These properties determine the appearance and visual characteristics of the final plastic product.

Chemical Properties

Chemical properties encompass factors such as chemical resistance, reactivity, and stability. Understanding the chemical properties of plastic raw materials is essential for ensuring compatibility with different environments and substances.

Mechanical Properties

Mechanical properties include tensile strength, flexibility, impact resistance, hardness, and elasticity. These properties determine the structural integrity and performance of plastic products under different load conditions.

Manufacturing Process of Plastic Raw Materials

The manufacturing process of plastic raw materials involves several stages, including polymerization, compounding, and shaping. The process begins with the extraction of raw materials, followed by refining and converting them into monomers. These monomers are then polymerized to form long chains of polymers, resulting in the desired plastic raw material.

Applications of Plastic Raw Materials

Plastic raw materials find extensive applications across various industries due to their versatile properties. Some key application areas include:

Packaging Industry

Plastic raw materials are widely used in packaging films, bottles, containers, and bags due to their lightweight, durability, and barrier properties.

Automotive Industry

Plastics play a vital role in the automotive industry, replacing traditional materials in components such as dashboards, bumpers, interior trims, and fuel tanks. Their lightweight nature contributes to fuel efficiency.

Construction Industry

Plastic raw materials are utilized in the construction industry for pipes, fittings, insulation materials, roofing membranes, and windows due to their durability, low cost, and resistance to corrosion.

Electronics Industry

Plastics are extensively used in the electronics industry for manufacturing casings, connectors, circuit boards, and insulation materials due to their electrical insulation properties and ease of fabrication.

Medical Industry

Plastic raw materials find applications in the medical industry for producing medical devices, equipment, and packaging materials. They offer properties like sterilizability, transparency, and biocompatibility.

Consumer Goods

Plastics are used in various consumer goods, including appliances, furniture, toys, and utensils, due to their versatility, aesthetics, and cost-effectiveness.

Textile Industry

Plastic raw materials are utilized in the textile industry for synthetic fibers, such as polyester and nylon, due to their strength, durability, and ease of dyeing.

Agriculture Industry

Plastics are used in agriculture for applications like mulch films, irrigation pipes, greenhouse coverings, and seed trays, providing benefits such as water conservation and crop protection.

Others

Plastic raw materials have applications in numerous other sectors, including sports and leisure, aerospace, telecommunications, and energy, showcasing the versatility of plastics.

Environmental Impact of Plastic Raw Materials

As plastic usage continues to grow, addressing the environmental impact of plastic raw materials has become crucial. Some measures to mitigate their impact include:

Recycling

Promoting and implementing effective recycling programs can significantly reduce the amount of plastic waste sent to landfills and minimize the need for virgin plastic production.

Waste Management

Improving waste management practices, including proper disposal and collection systems, prevents plastic pollution in oceans, rivers, and other natural habitats.

Biodegradable Alternatives

Developing and adopting biodegradable alternatives to traditional plastics can help reduce their long-term environmental impact and promote a circular economy.

Future Trends and Innovations

The field of plastic raw materials is witnessing continuous advancements and innovations. Some emerging trends include the development of bioplastics, bio-based materials, and the use of recycled plastics in manufacturing processes. These innovations aim to reduce environmental harm and promote sustainability.

Conclusion

Plastic raw materials play a vital role in modern society, enabling the production of a wide range of products across various industries. Understanding the types, properties, and applications of plastic raw materials is essential for making informed decisions regarding their usage. It is crucial to prioritize sustainable practices and explore innovative solutions to mitigate the environmental impact of plastic raw materials.

For more information or any types of consultation, you can contact us and get the best guide you want.

Frequently Asked Questions (FAQs)

1. What are the most commonly used types of plastic raw materials?

The most commonly used types of plastic raw materials include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), polyethylene terephthalate (PET), acrylonitrile butadiene styrene (ABS), polyurethane (PU), and others.

2. How is plastic raw material manufactured?

Plastic raw materials are manufactured through processes such as polymerization, compounding, and shaping. These processes involve the conversion of raw materials into monomers, followed by polymerization to form the desired plastic material.

3. What are the key properties of plastic raw materials?

Plastic raw materials possess physical, chemical, and mechanical properties. Physical properties include density, transparency, and color. Chemical properties encompass resistance and reactivity, while mechanical properties include tensile strength, flexibility, and impact resistance.

4. What are some major applications of plastic raw materials?

Plastic raw materials find applications in industries such as packaging, automotive, construction, electronics, medical, consumer goods, textile, agriculture, and more.

5. How can we mitigate the environmental impact of plastic raw materials?

Mitigating the environmental impact of plastic raw materials can be achieved through measures such as recycling, improving waste management practices, and exploring biodegradable alternatives to traditional plastics.